Since 1953

Printing techniques

Master Prints: Exploring Cutting-Edge Techniques in Printmaking.

Ways to print

We preserve the craft to give soul and craftsmanship to the creativity of today's design professionals. We help combine the possibilities of artisanal techniques with the full potential of digital tools and artificial intelligence. At Vintage Printing, we believe that traditional techniques hold incredible creative potential. We help you learn these printing techniques so you can unleash your creativity.

Our commitment to craftsmanship and authenticity is reflected in every technique we apply. From the timeless elegance of typography to the meticulousness of engraving, we offer you a journey through time where each print is a unique work of art.

Discover the charm of classic printing methods and how they can enhance your projects with a touch of distinction. At Vintage Printing, we merge the legacy of the past with the innovation of the present, offering you not just a printing service, but an experience that highlights the beauty in every printed detail. Welcome to a world where printing is an art and each technique tells a unique story!

We preserve the craft to give soul to today's creativity.

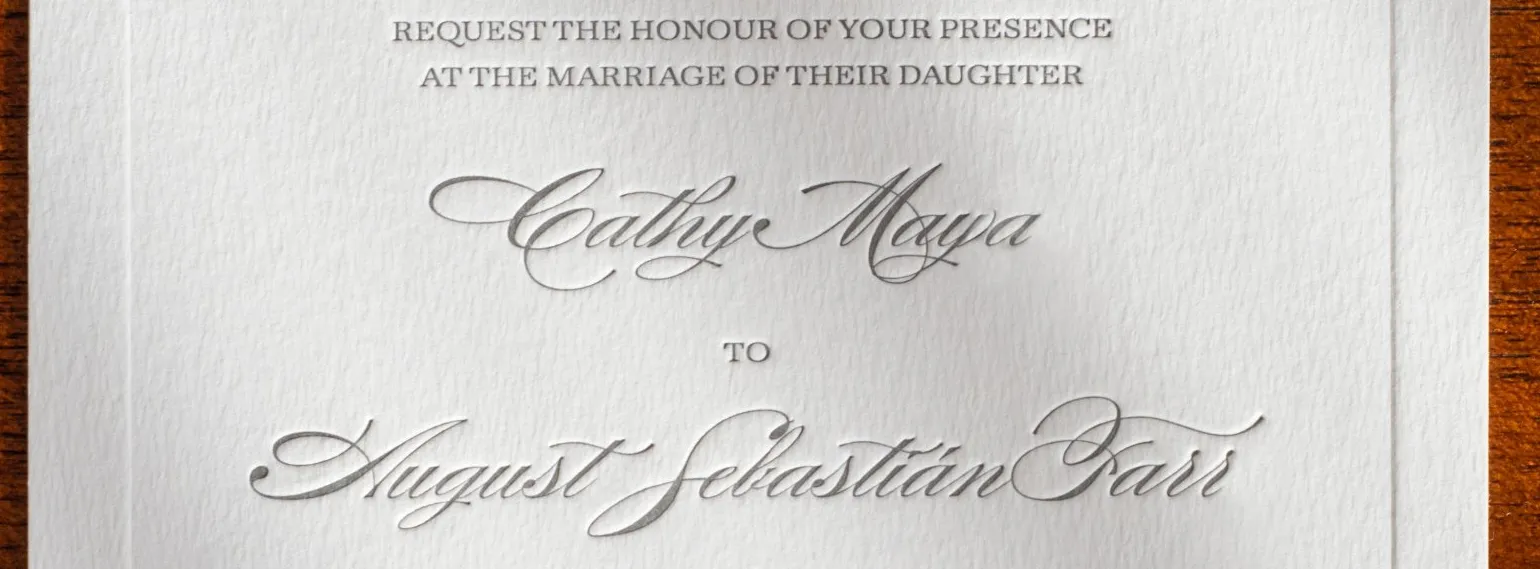

Letterpress or typographic printing

Stamping or hot stamping

Stamping is very similar to Letterpress in its technique, which replaces ink with strips of metallic material that are transferred to the paper by heating the mold, so that the projection of the hot mold when coming into contact with the stamping strip and the paper, the letters and/or drawing of the mold are transferred.

Dry blow

We call it Dry Stamping when we stamp a mold on the paper in such a way that the letters or drawing stand out from the paper, making them legible due to the play of light and shadows produced when the light hits the printed paper.

Stamped Relief or Authentic Relief

This is the printing method that achieves the highest level of quality and finesse in raised lines. This is the technique used to print banknotes, for example. It consists of filling a steel or bronze mould made by hand with ink using a burin and containing the negative drawing or text to be printed. Before coming into contact with the paper, the stamping machine cleans the excess ink from the mould, and then exerts enormous pressure between the paper introduced into the machine by hand and the counter-mould (positive drawing of the mould made with cardboard) so that the ink inside the mould saturates the fibres of the paper being printed, leaving a clear and crisp raised impression.

With this Stamped Relief technique, you can also achieve dry stamping with various levels of relief, achieving a 3D effect on the paper. Widely used in wedding invitations for initials, coats of arms or crowns.

Thermorelief or False Relief

This is the printing method that achieves the highest level of quality and finesse in raised lines. This is the technique used to print banknotes, for example. It consists of filling a steel or bronze mould made by hand with ink using a burin and containing the negative drawing or text to be printed. Before coming into contact with the paper, the stamping machine cleans the excess ink from the mould, and then exerts enormous pressure between the paper introduced into the machine by hand and the counter-mould (positive drawing of the mould made with cardboard) so that the ink inside the mould saturates the fibres of the paper being printed, leaving a clear and crisp raised impression.

With this Stamped Relief technique, you can also achieve dry stamping with various levels of relief, achieving a 3D effect on the paper. Widely used in wedding invitations for initials, coats of arms or crowns.